Description

Sistem pengukuran ketebalan lapisan vakum bekerja berdasarkan prinsip bahwa transmitansi (kerapatan optik) material pada panjang gelombang cahaya tertentu sebanding dengan ketebalan lapisan. Keseragaman material dicapai dengan memantau transmitansi optik (kerapatan optik) material. Semakin tebal lapisan, semakin tinggi kerapatan optiknya, dan semakin rendah transmitansinya. Selama cahaya dapat menembus material, kualitas produk dapat dikontrol dengan memantau transmitansi (kerapatan optik).

Perangkat ini mampu mengukur ketebalan lapisan pelapis produk secara daring dan waktu nyata (real-time), yang membantu memahami dan memantau kualitas produk dalam proses produksi, menemukan masalah, dan menyesuaikan proses sedini mungkin, sehingga dapat meningkatkan kualitas produk dan mengurangi tingkat skrap. Sistem pengukuran ketebalan lapisan vakum ini banyak digunakan dalam mesin pelapis vakum konsentrasi, pelapis kaca, lini produksi kaca, lini produksi pelapis, dan bidang lainnya.

LS153 Vacuum Coating Thickness Measuring System Struct &Operation

Note: LS153 vacuum coating thickness measuring system is an upgraded model of LS152. LS152 has one controller to control 3 sets of probes and the signals are processed by the controller. LS153 signals are processed in the probes without the need of a controller.

LS153 Vacuum Coating Thickness Measuring System Introduction

RS485 communication interface/MODBUS communication protocol

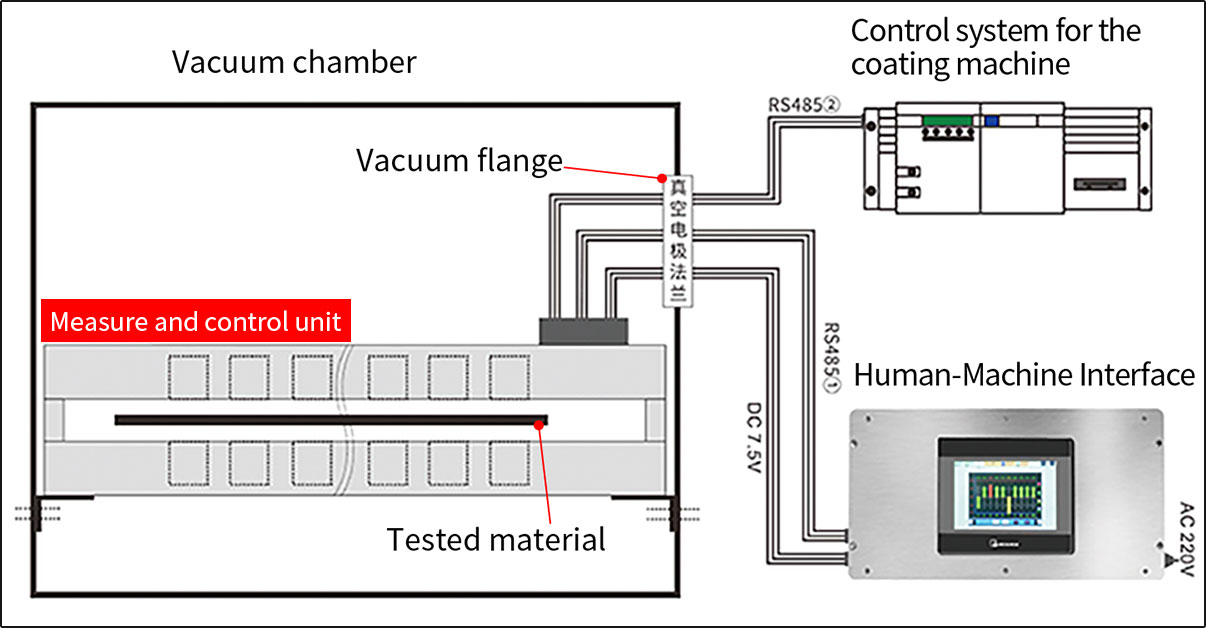

The instrument provides dual RS485 communication interface and standard MODBUS communication protocol, which is convenient for communication with PLC, Single Chip Microcomputer, human-machine interface, kingview, computer and so on. The optical density data can be read on the coating machine to realize control automation (closed-loop control).

System Composition

The equipment is mainly divided into three parts: measure and control units, human-machine interface, computer real-time monitoring software (optional).

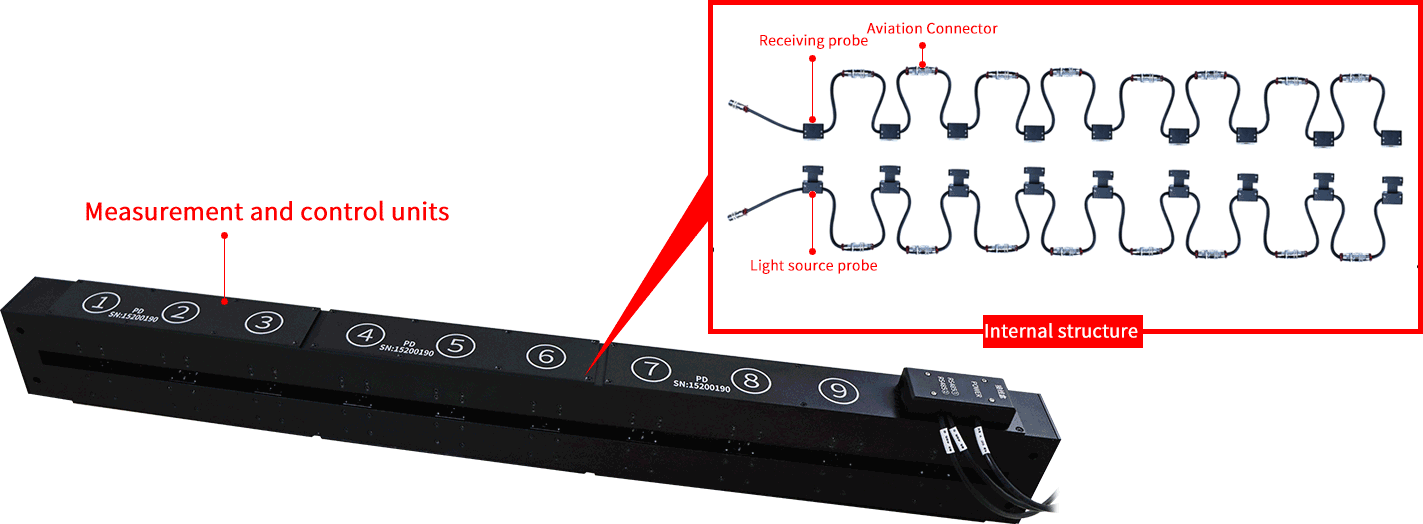

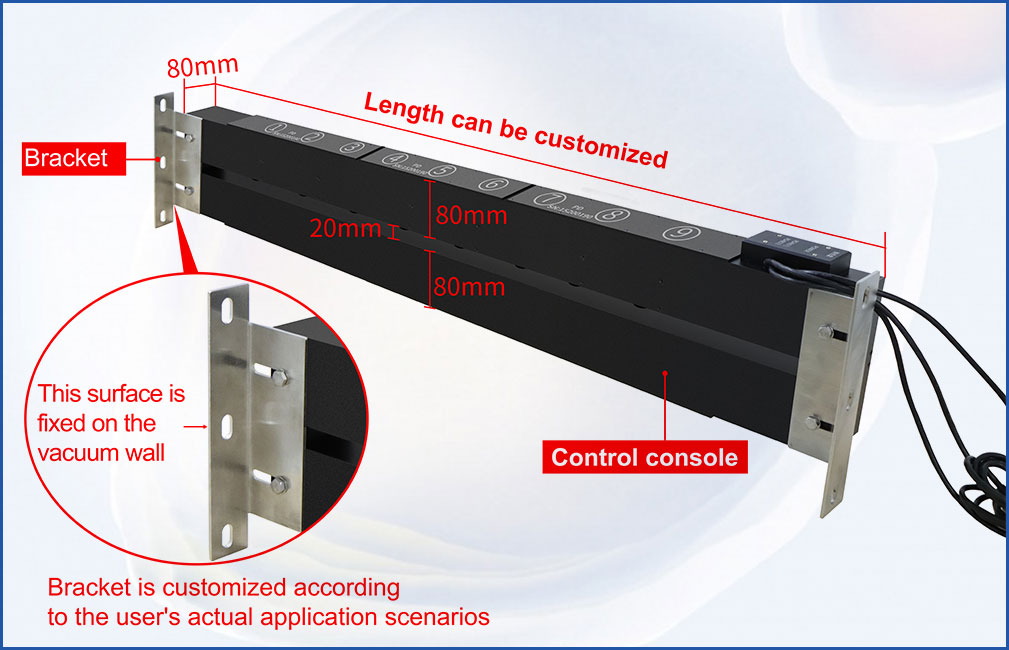

Independent digital probe design, easy to operate and install

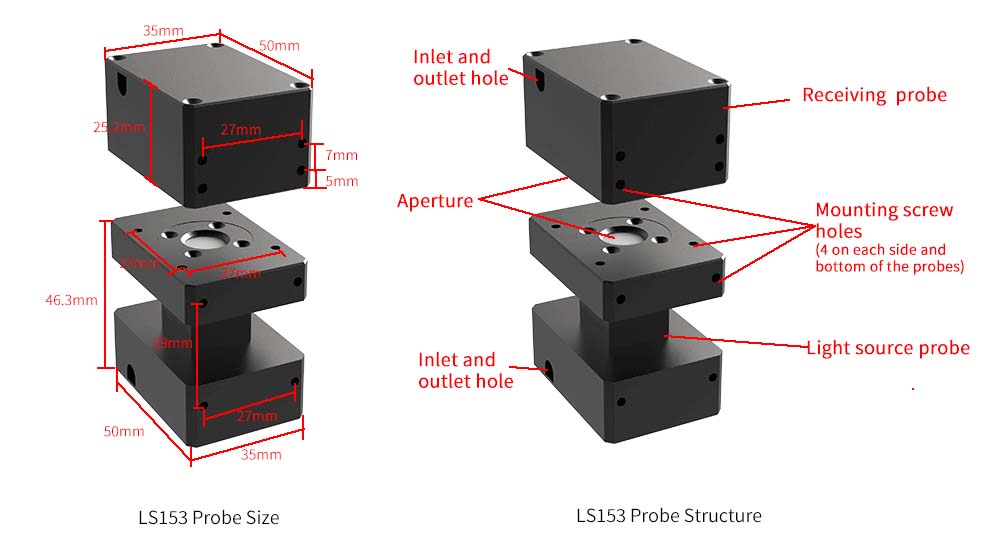

A set of probes contains a light source probe and a receiver probe, with 4 mounting screw holes on the light hole side and 4 mounting screw holes on the side of the probe for easy installation.

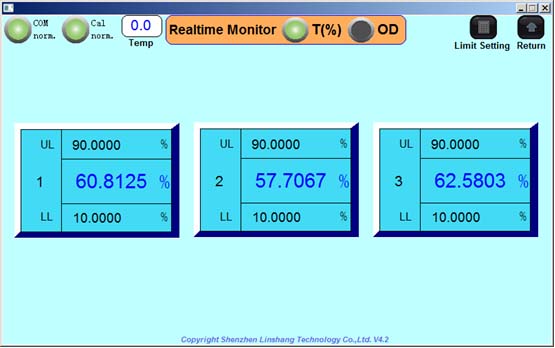

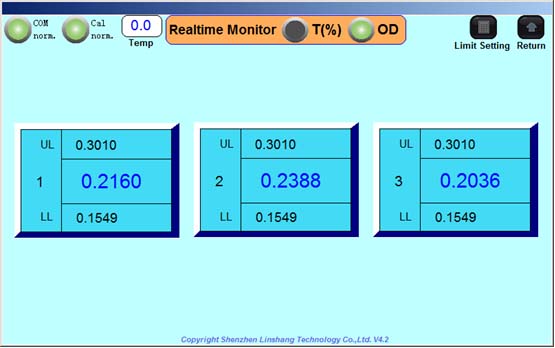

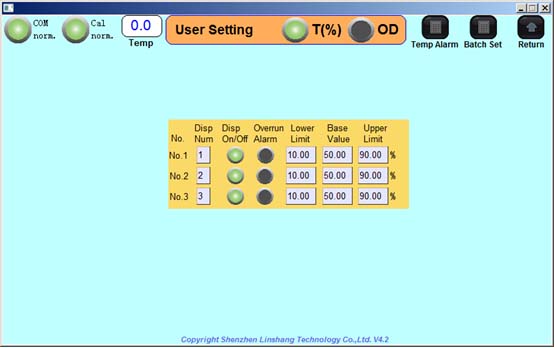

Computer real-time monitoring system (optional)

Real-time monitoring of the data, including real-time display, histogram, setting of upper and lower limits, real-time curve and alarm when the limit is exceeded. The transmittance and optical density display can be switched freely.

Features

1.Ultra-small digital probe, super easy to use and install, only 6 wires to be connected.

2.The instrument use optical non-contact measurement, without direct contact with the test material. It will not cause damage to the tested material.

3.RS485 interface and MODBUS communication protocol, which is convenient for communication with PLC, Single Chip Microcomputer, human-machine interface, kingview, computer and so on, and can achieve closed-loop control by communicating with the coating machine.

4.The vacuum coating thickness measuring system has high measurement accuracy.

5.The instrument use modular design, each module is connected by aviation connector, single point is removable, which is convenient for future maintenance.

6.With dust-proof design, dust does not affect the inside of the gyroscope. Customers just need to clean the front glass of the probe.

7.The instruemtn has over-limit alarm function and can intelligently control production quality. The instrument can reduce dependence on manual operation and improve production efficiency and quality.

8.The instrument has a temperature compensation function, the value is stable, allowing the use of high-temperature environments.

9. The instrument is equipped with automatic calibration and manual calibration function, which can be freely set by the user according to the need.

10.Equipped with human-machine interface, real-time monitoring of the data, including real-time display, histogram, upper and lower threshold settings, over-limit alarm, RS485 ② communication parameter settings, etc. The transmittance and optical density display can be switched freely.

System Parameters

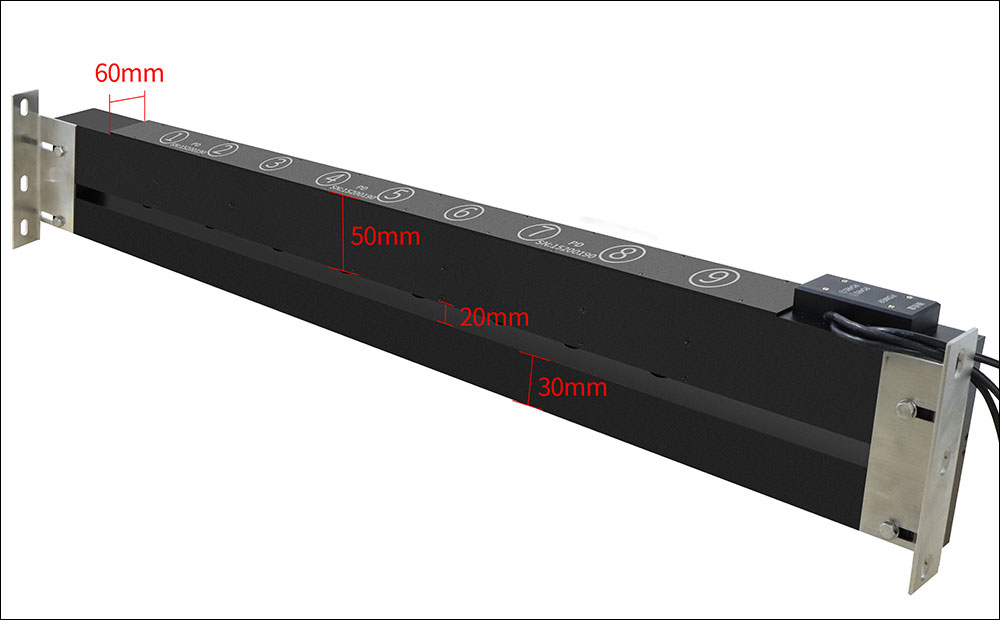

| Parameters | LS153 |

|---|---|

| Test Wavelength (Optional) | Green light: 530nm; Infrared: 850nm |

| Measuring Spot | 5mm |

| Transmittance Measurement Accuracy | ±1% |

| Transmittance Resolution | 0.005% |

| Optical Density Measurement Range | 0.00 OD – 6.00 OD |

| Optical Density Resolution | 0.01 OD for 0.00-3.00 OD 0.05 OD for 3.00-5.00 OD 0.15 for 5.00 – 6.00 OD |

| Maximum Measurement Points | 45 points |

| Distance Between Adjacent Probe | Minimum distance of 35mm |

| Distance Between Receiving Probe and Light Source Probe | 20mm |

| Temperature Range | -10°C – 60°C |

| Storage Temperature | -20°C – 70°C |

| Relative Humidity | less than 85%, no condensation |

| Data Refresh Cycle | Normal mode 300ms/ Fast mode 100ms |

| Communication Interface | Dual RS485 |

| Communication Protocol | MODBUS protocol |

| Dimension | 80mm(W)*180mm(H)*L (Customized) |

| Vacuum Flange Electrode Cores | 6 ( RS485①+DC7.5V) 9 ( RS485①+ RS485②+DC7.5V) |

| Power Supply | 220V AC/50Hz |

Kontak Kami :

Telp/Whatsapp : 0812 1248 2471

Email : alfin@testindo.com

Reviews

There are no reviews yet.