Description

Features:

1. The force measurement of this machine adopts high-precision loadsensor, microcomputer program control, electro-hydraulic proportional hydraulic loadingsystem and other technologies.

2. Use the positioning ruler (self-provided) to adjust the position of the sleeper sothatthe load center coincides with the center of the pressure plate.

3. According to the set working procedure, the piston moves freely.

4. Equipped with three high-precision spoke sensors to ensure accurate data of threeseparate pressure points, and equipped with special LED crack observationlights. Inorder to facilitate the sleeper test of foreign standards, the fulcrumcan be adjusted.

5. The loading process is adjusted with the variable structure PID control algorithm, theconstant speed control error is ≤5%, and the pressure holding control error is ≤0.5%.

6. Loading speed Uniform loading. 7. The static load point can be set arbitrarily, and the data result report is automaticallyprinted.

Main technical parameters and specifications:

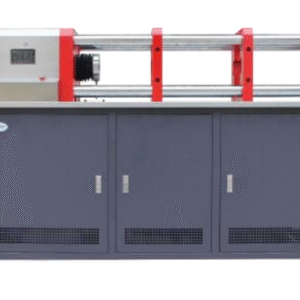

1. Model Specification: TSY-500

2. The Maximum Load Value under the Rail (kN): 500

3. Load Indication Accuracy: ±1%

4. Initial Load after Placing the Sleeper(kN): <20

5. Loading Speed (N/s): 3000±300

6. Hold Time (s): 180

7. Piston Maximum Stroke (mm): 250

8. Adjustable Under-rail Loading Distance (mm): 600, 700, 800

9. Adjustable Loading Distance in the Rail (mm): 600, 1500

10. Test space: Distance between Upper and Lower Supports (mm): 430

11. Test space: Distance between Four Columns (mm): 820, 900

12. Dimensions: Host (mm): 1720×990×2266

13. Carriage (mm): 3390×700×135

14. Control Cabinet (mm): 1210×770×1020

Related Parameters of Hydraulic Pump Station:

15. Rated Pressure: High Pressure Oil Pump 31.5Mpa

16. Rated Displacement: High Pressure Oil Pump 25ml/rec

17. Motor Power: 1.2kW ,Speed 980rpm

18. Power Supply Voltage: AC380V±10%

Contact Us:

– Telp & Whatsapp 0812-1248-2471

– Email alfin@testindo.com

Reviews

There are no reviews yet.